Weld seam cleaning device TIG-MAX®

- Accelerate cleaning processes by up to 70%

- Save up to 3 working days on 1000m of welding seam

- Up to 1000-meter brush durability for less consumption

- 24/7 continuous operation without mandatory breaks and without overheating

- 100% MADE IN GERMANY

Fast cleaning

Accelerate cleaning processes by up to 70% – less effort, more productivity.

Low material costs

Up to 1000 meters brush durability & economical fluid consumption – reduced material costs.

24/7 continuous operation

Cleaning without mandatory breaks and without overheating for maximum readiness.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe fastest, safest, and most efficient stainless steel cleaning for professional use

Weld seam cleaning device: Small measure, big impact

Overview of our devices

TIG-MAX® XT 2500 - The Beginner

TIG-MAX® XT 4000 – The Smart

TIG-MAX® XT 6000 – The Allrounder

TIG-MAX® XT 7000 – The Powerful

TIG-MAX® XT 9000 – The Flagship

The most powerful model with 4000 W for professional industrial applications. It cleans, polishes, passivates, and marks stainless steel efficiently without pickling chemicals. Inverter technology and stepless control offer maximum control and highest quality.

Complete packages with accessories

The fastest, safest, and most efficient stainless steel cleaning for professional use

Avoid alternative methods!

Device comparison

| Property | XT 9000 | XT 7000 | XT 6000 | XT 4000 | XT 2500 |

|---|---|---|---|---|---|

| Output Load | 4000 W | 2500 W | 2880 W | 1440 W | 456 W |

| Dimensions (LxWxH in mm) | 380 x 170 x 315 | 380 x 170 x 315 | 350 x 133 x 213 | 350 x 133 x 213 | 240 x 130 x 160 |

| Protection Class | IP23 | IP23 | IP23 | IP23 | IP23 |

| Weight | 17.0 kg | 17.0 kg | 7.5 kg | 7.0 kg | 6.0 kg |

| Line Voltage | 230 V | 230 V | 230 V | 230 V | 230 V |

| Stepless Adjustment | |||||

| Cleaning | |||||

| Passivation | |||||

| Polishing | |||||

| Marking |

TIG-MAX® - What you need to know! All information in the video:

Our inverter technology: The difference is enormous!

Our inverter is an electronic component integrated into the TIG-MAX® XT devices. It ensures that electricity is converted particularly efficiently and controlled. Unlike traditional transformers, an inverter can adjust the electricity steplessly, specifically adapt it, and thus make cleaning significantly more effective.

Advantages of inverter technology with TIG-MAX®:

- Stepless power adjustment for precise adaptation to material & degree of contamination

- Constant performance even with long cables or fluctuating line voltage

- High efficiency for more performance with less energy consumption

- Lightweight, making it ideal for mobile use

- 100% duty cycle for work without enforced breaks due to overheating

Advantages of our weld seam cleaning devices

Absolute control

Ultra-light & extremely mobile

Mobility & Comfort

24/7 continuous operation

Maximum corrosion protection

Much more than just cleaning!

Low wear

Easy operation with top performance

What are you waiting for?

Get started now and benefit from the advantages of our machines.

Applications

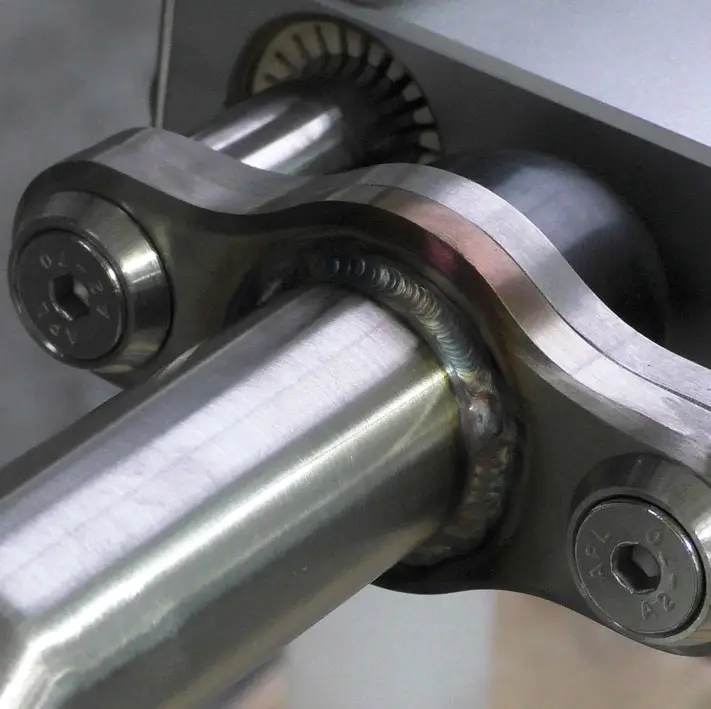

- Plant and Machinery: Clean visible welds, remove discoloration, passivation for corrosion protection

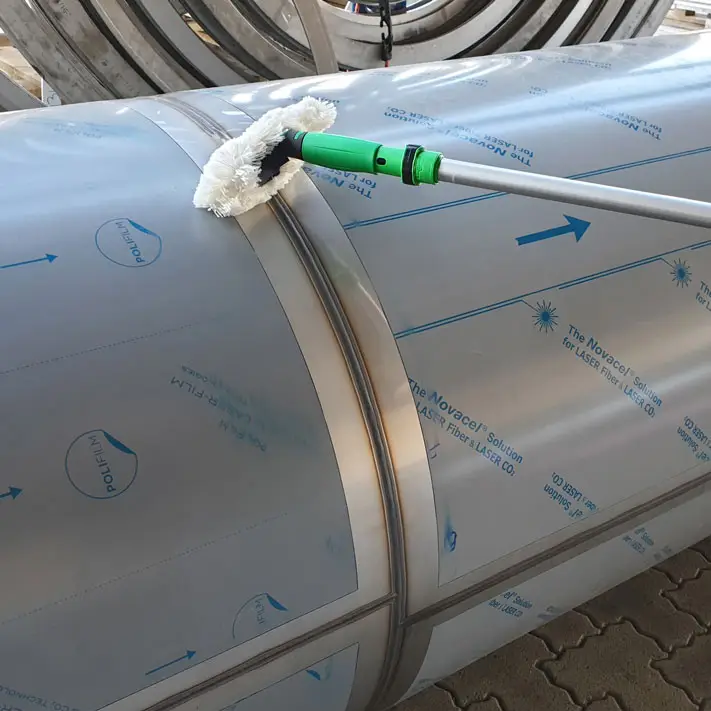

- Food Industry: Hygienic cleaning of tanks, conveyors, and pipelines, NSF-compliant application

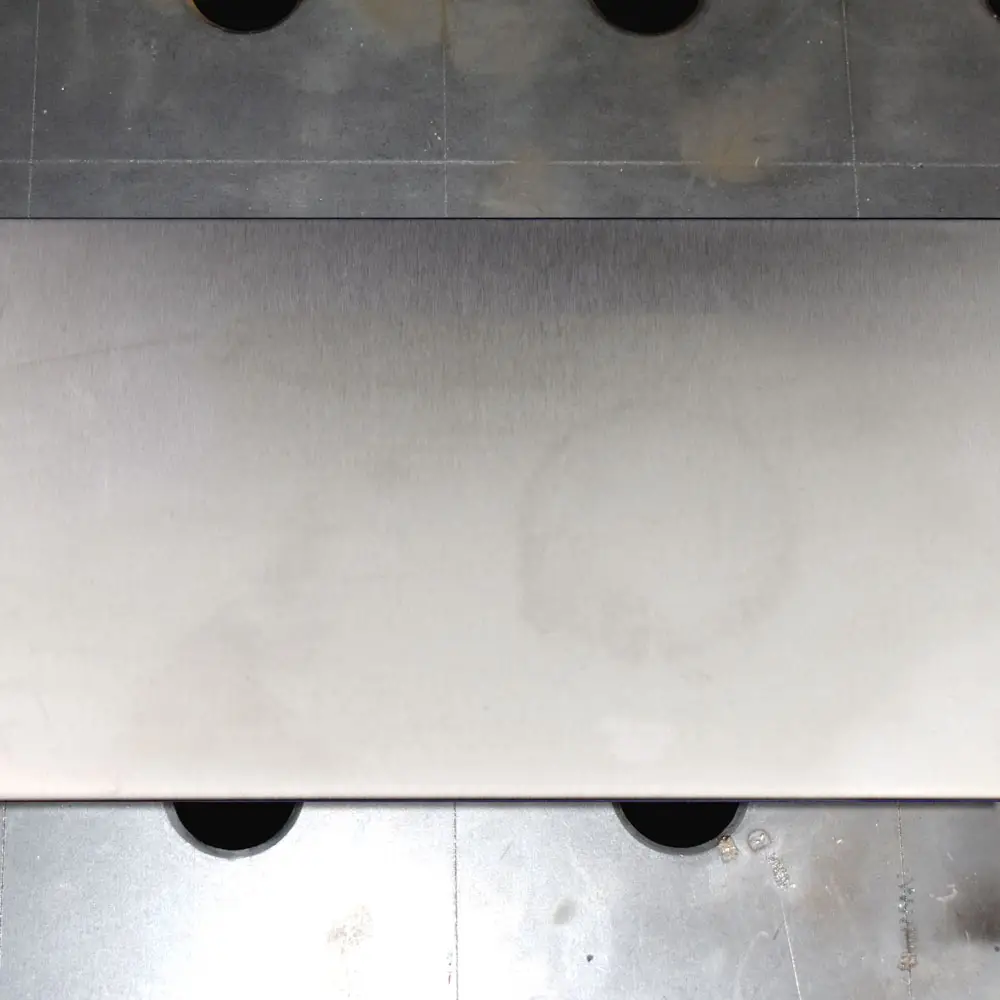

- Pharmaceutical and Medical Technology: Residue-free cleaning, polish for smooth surfaces, use in clean rooms

- Shipbuilding and Offshore: Weld cleaning on stainless steel outdoors, passivation for saltwater resistance

- Metal and Construction Industry: Cleaning and polishing stainless steel railings and facade parts, stain protection

- Beverage and Brewing Industry: Cleaning tanks and pipelines, pH-neutral disposal, no residues

- Vehicle and Special Vehicle Construction: Weld processing on visible stainless steel parts, polishing, corrosion protection

We redefine weld cleaning

More time & productivity

Lower costs

Perfect weld quality – without rework

Maximum safety & environmental friendliness

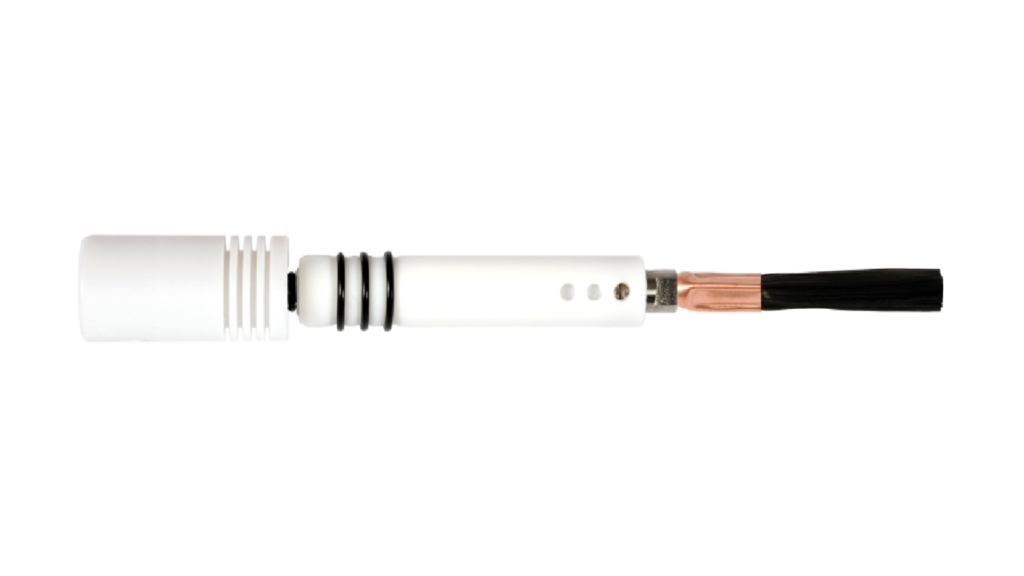

Our accessories make the difference

Cleaning brush

Shaped handles

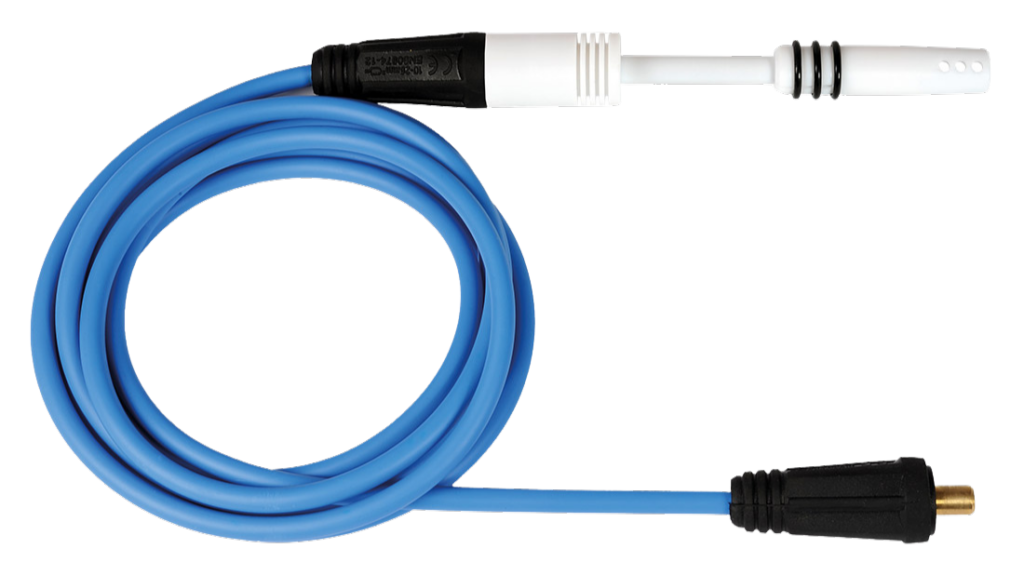

Cables

Liquids

Satisfied customers