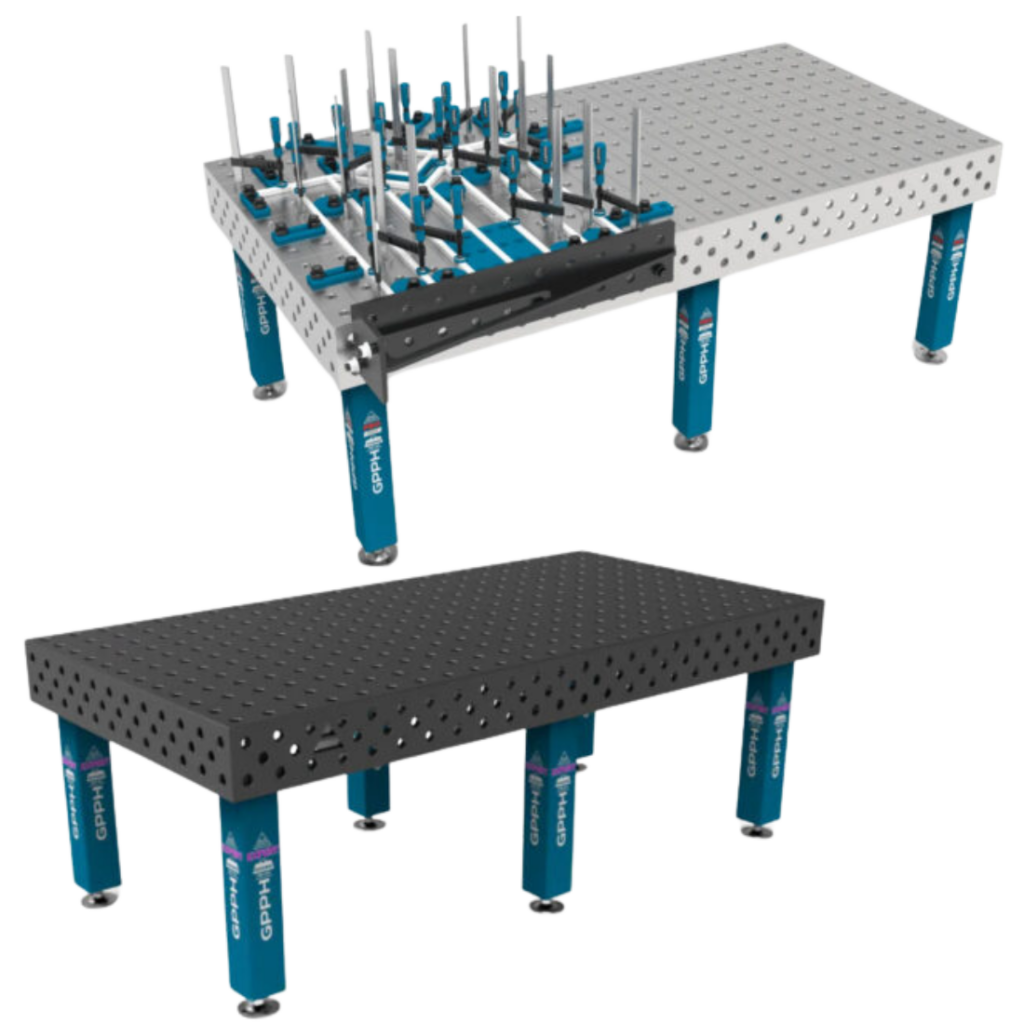

Welding tables for every requirement – individually tailored to your processes

Whether you are welding single parts, assembling fixtures, or producing complex assemblies: A suitable welding table forms the foundation for clean, precise, repeatable results. We support you in selecting and configuring welding tables that exactly match your requirements – in workshops, mechanical engineering, or series production.

We help you with this

Our solution competence ranges from compact models for smaller workstations to large, robust tables for industrial applications. We consider aspects such as load capacity, grid geometry, height adjustment, mobility, and expandability with accessories like supports, clamping systems, or roll feet.

Mobile welding tables

For changing workplaces or workshops with limited space, mobile welding tables are the right choice. Roll feet or compact designs allow easy transport within production. The working height can be adjusted depending on the model, ensuring ergonomic and safe working at all times.

Your advantages:

- Flexibly usable at changing workstations

- Easy to maneuver with wheels or handle systems

- Can also be used as a supplement to stationary workstations

- Ideal for repair, service, or flexible assembly lines

Stationary welding tables

Stationary solutions are ideal for fixed workplaces where precise welding and assembly operations are regularly carried out. The robust tabletop made of high-quality material ensures absolute flatness, even under heavy loads. Thanks to a continuous grid system, components can be flexibly fixed, and reproducible setups can be arranged – a clear advantage for consistent quality and efficient workflows.

Your advantages

- High load capacity – for heavy components and fixtures

- Dimensional stability and flatness across the entire surface

- Expandable with accessories such as rulers, stops, or stainless steel supports

- Ideal for welding robots and precise series production

Together to the optimal solution – we provide you with comprehensive advice

A welding table is not a standard solution – it should be precisely tailored to your processes, workpieces, and spatial conditions. That’s why we accompany you from the requirement to the final implementation with comprehensive advice and configuration support. Whether standard dimensions or custom-made – together we find the right solution for your application.