TIG-MAX® XT 9000

Cleaning, Polishing, Passivation & Marking – all faster, stronger, and more precise.

The TIG-MAX® XT 9000 is the most powerful stainless steel cleaning device in our range. With 4000 W output, a large accessory package, and continuous 24/7 operation, it is the top choice for industry, series production, and demanding applications.

The most important product features at a glance

- 4-in-1 function: Cleans, polishes, passivates, and marks – in just one operation

- Maximum performance: 4000 W – the most powerful device in the TIG-MAX® XT series

- Extremely robust: For hard continuous use in shift work, construction sites, and manufacturing

- 100% duty cycle: Automatic cooling, no performance loss, no breaks

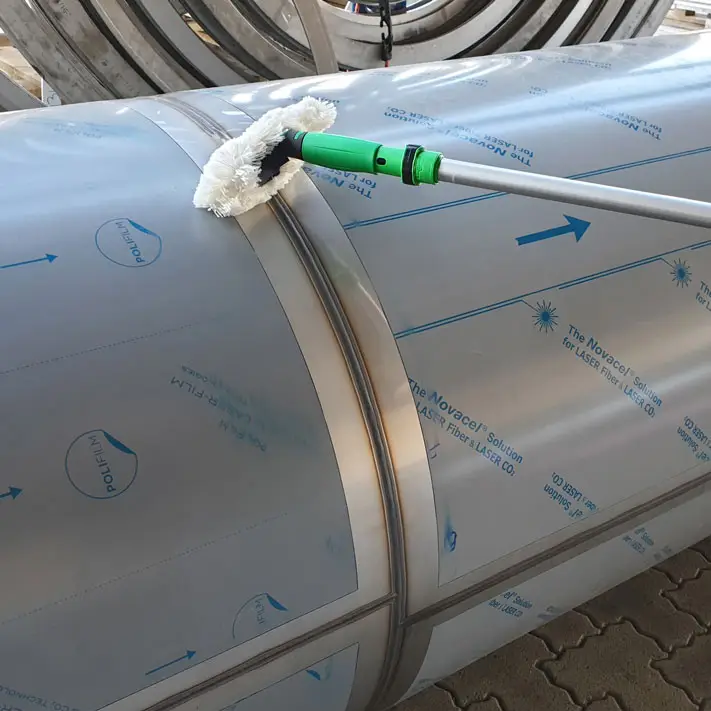

- Durable Superbrush technology: Perfect results, even on large surfaces and thick seams

- Precise current adjustment: Material- & task-specific settings for highest surface quality

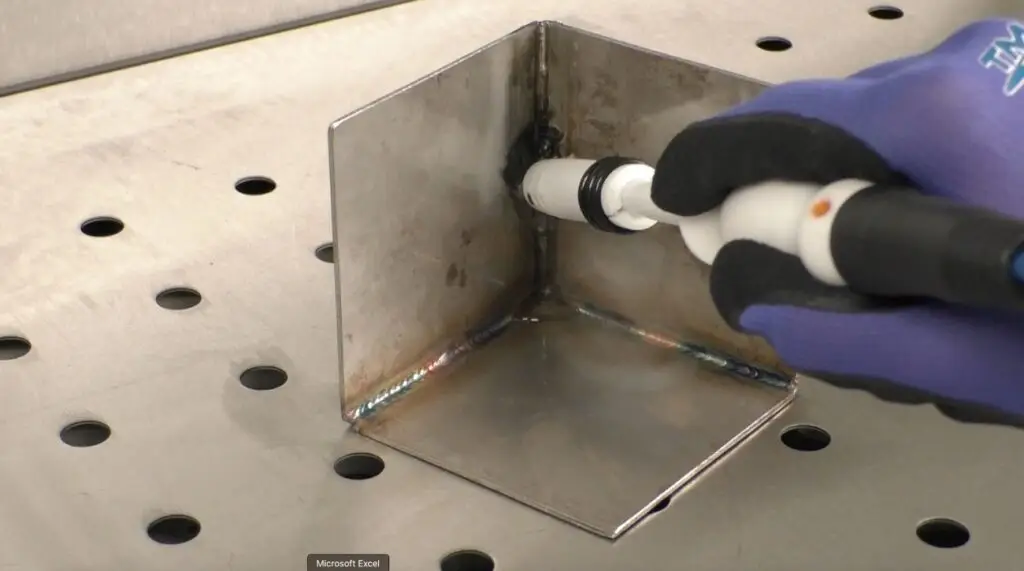

- Marking function included: Permanently marking logos, QR codes, serial numbers, and lettering on stainless steel

Technical data

- Output 4000 W

- Dimensions 385 × 170 × 315 mm

- Protection class IP23

- Weight 17.0 kg

- Mains voltage 230 V

- Functions: Cleaning, Polishing, Passivation, Marking

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationScope of delivery (Complete set)

1× TIG-MAX® XT 9000 stainless steel cleaning device

1× Form handle cable complete set “Superbrush” (6 m)

1× Ground cable (6 m)

5× Carbon fiber cleaning brushes “Superbrush”

1× Double brush adapter

1× Double slide-insulating sleeve

1× TC-275 cleaning & polishing electrolyte (1 L)

1× TC-510 neutralizer (1 L)

5× Microfiber cloths “Superclean”

1× HSF liquid container

1× HSF pressure pump sprayer (1.2 L)

1× Safety goggles, 1× Respiratory protection mask, 1× Chemical gloves

1× HSF wire brush “Mini”

1× Transport case for TIG-MAX® XT 9000

1× Operating instructions

1× TIG-MAX® XT catalog

The effect of our devices

Functions of the XT 9000 at a glance

Cleaning

- from small seams to large surfaces

- without attacking the surface structure

- removes discoloration + white spots, edges, and streaks in seconds

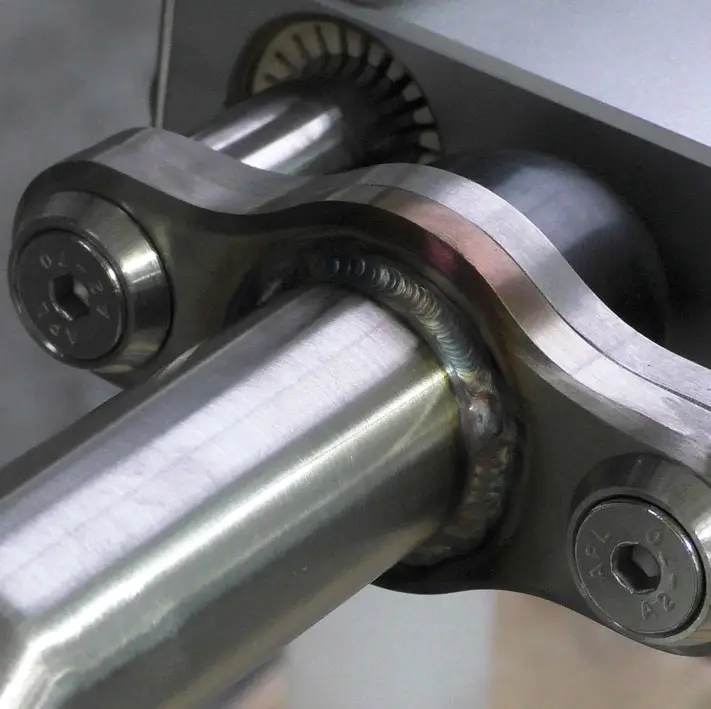

Polishing

- from various components

- from welds formed later on electropolished material

- from residual deposits or burn marks left behind

- from small scratches

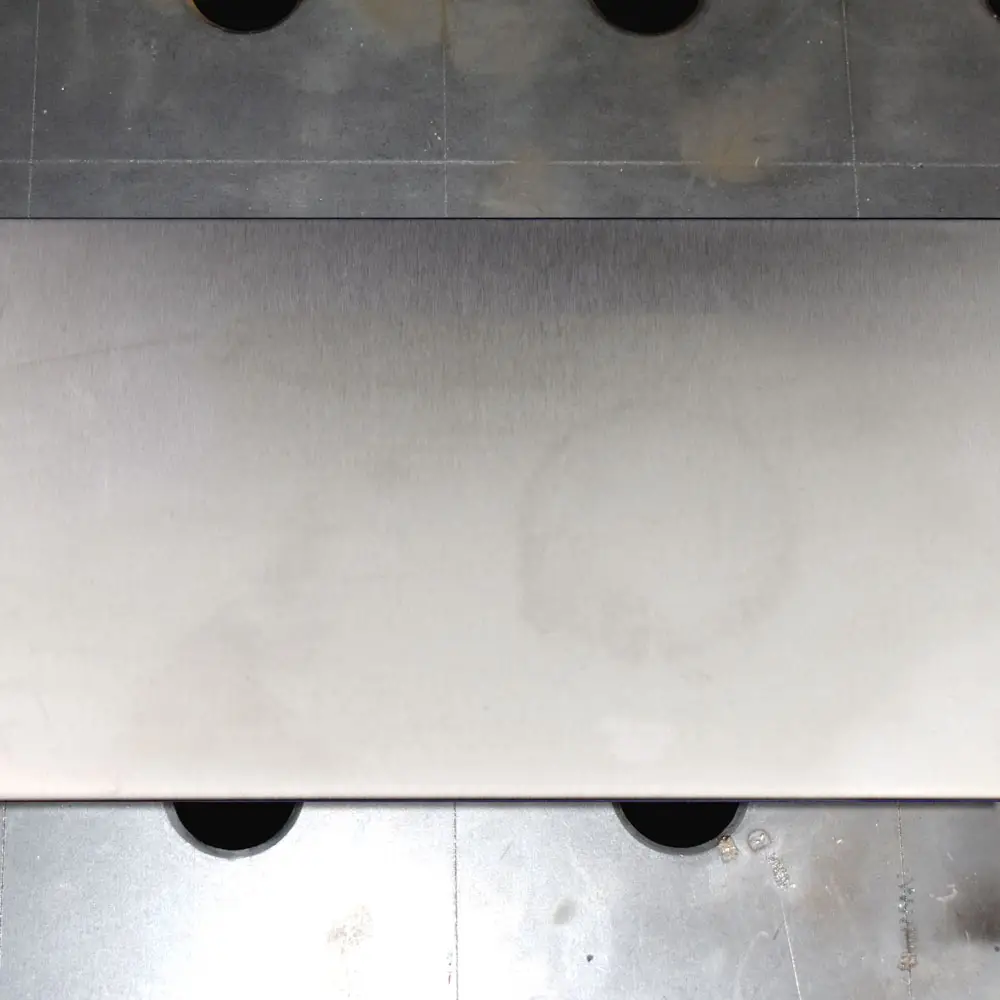

Passivation

- for 100% protection against corrosion (rust)

- for higher quality

- for greater customer satisfaction

Marking

- of private labels

- of graphics

- of inscriptions (e.g. product names, part numbers)

- of QR codes

- on your products

Your advantages with our device: TIG-MAX® XT 9000

- Rapid cleaning Up to 70% faster than manual cleaning: TIG-MAX® XT cleans, polishes, and passivates in one step. This massively reduces working time, relieves your skilled workers, and increases the throughput speed of your components.

- Safe, acid-free, worry-free The TIG-MAX® fluid is 100% acid-free – no danger for skin, airways, or environment. This eliminates expensive protective measures, disposal efforts, and risk assessments – more safety with less bureaucracy.

- Reduce costs, increase efficiency Durable carbon fiber brushes with up to 1000 m cleaning length and minimal fluid consumption save you cash. You need to buy spare parts less frequently, have less consumable stock – and significantly reduce your operating costs.

- Continuous operation instead of forced break Thanks to intelligent cooling, the TIG-MAX® XT devices run 24/7 – without overheating or loss of performance. This means: No production stops, no waiting times, full utilization in shift operation and industrial environments.

- Precise adjustment, perfect results With the stepless power regulation, you can adjust current and intensity precisely to the material, degree of contamination, and task at hand. This prevents over-cleaning, protects sensitive surfaces – and always delivers reproducible top results.

- More possibilities, less rework Whether thick weld seams, intricate components, or sensitive electro-polished surfaces – with the versatile accessory system of the TIG-MAX® XT devices, you can clean and mark even hard-to-reach areas reliably. This saves rework, improves the finish, and ensures consistently high quality – even with complex geometries.

Our inverter technology: The difference is huge!

Our inverter is an electronic component built into the TIG-MAX® XT devices. It ensures that the power is converted especially efficiently and controlled. Unlike classic transformers, an inverter can regulate the power steplessly, adjust it precisely, and make the cleaning process significantly more effective.

Advantages of inverter technology with TIG-MAX®:

- Stepless power adjustment for precise adaptation to material & degree of contamination

- Constant performance even with long cables or fluctuating mains voltage

- High efficiency for more power with less energy consumption

- Lightweight, making it ideal for mobile use

- 100% duty cycle for work without forced breaks due to overheating

Why TIG-MAX® instead of pickling or pads?

- No use of hazardous chemicals

- No dust, no health risks

- No need for repolishing

- No restrictions in hygienic areas

Convince yourself now

Lightning-fast cleaner and corrosion-resistant weld seams – without risks and with maximum efficiency. A must for companies that professionally process stainless steel and want to save time, material, and costs. TIG-MAX XT – The best devices and cleaning liquids on the market!