Passivating stainless steel: What you need to know!

What is passivating stainless steel?

Passivating stainless steel is a chemical process that renews the metal’s natural protective layer and improves its corrosion resistance. Stainless steel contains chromium, which reacts with oxygen to form a thin chromium oxide layer. This layer protects the metal from rust and other environmental influences.

Mechanical processing, welding, or contact with aggressive media can damage or contaminate this protective layer. During passivation, the surface is treated with special acids, such as nitric or citric acid. These remove free iron particles and promote the formation of a new, dense chromium oxide layer.

Companies in the food, pharmaceutical, and chemical industries often use this process because stainless steel must meet the highest hygiene and corrosion resistance requirements. In maritime or industrial environments, where aggressive substances affect the material, regular passivation is essential to extend the lifespan of components and prevent damage from corrosion.

Why does stainless steel need to be passivated?

Stainless steel, especially non-rusting steel, contains at least 10.5% chromium. This chromium reacts with the oxygen in the environment and forms a thin, stable chromium oxide layer on the surface. This layer protects the underlying metal from further oxidation and corrosion. However, this natural passive layer can be damaged by mechanical processing, welding, or contact with aggressive chemicals.

Such damage leads to increased susceptibility to corrosion, particularly in the form of pitting or crevice corrosion. Targeted passivation restores the integrity of this protective layer, significantly improving the corrosion resistance of stainless steel.

How does stainless steel passivation work?

The passivation process begins with a thorough cleaning of the stainless steel part to remove contaminants such as oils, fats, or particles. The workpiece is then immersed in an acid bath, typically consisting of nitric or citric acid. These acids remove free iron from the surface and promote the formation of a dense chromium oxide layer.

The specific parameters of the process, such as acid concentration, temperature, and exposure time, vary according to the applied standard (e.g., ASTM A967, AMS2700, ASTM A380) and the specific stainless steel alloy. After the acid treatment, the workpiece is neutralized, typically through a bath in a sodium hydroxide solution, to remove remaining acid residues.

Finally, rinsing with deionized water and drying occur. The quality of passivation is often checked by tests such as the salt spray test to ensure corrosion resistance.

When is passivation necessary?

Passivation of stainless steel is particularly recommended in the following situations:

- After mechanical processing: Processes like grinding, milling or turning can damage the passive layer and leave free iron on the surface.

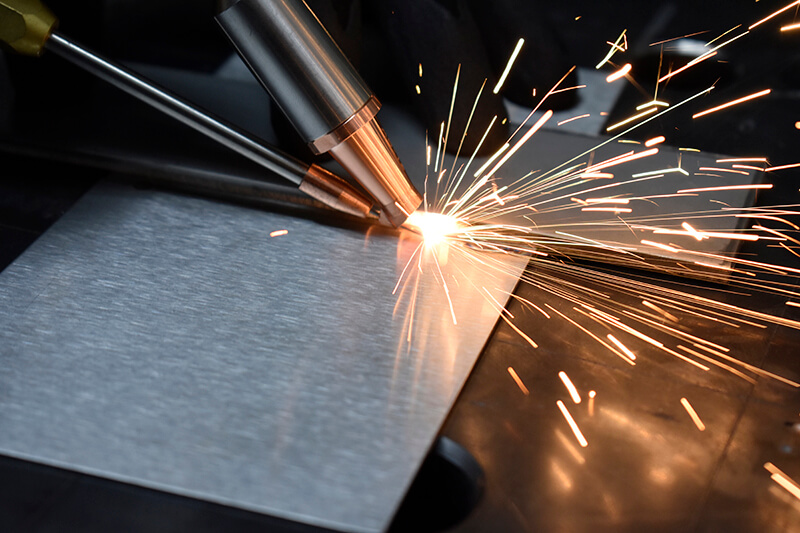

- After welding: The high temperatures during welding can destroy the chromium oxide layer and cause discoloration that impairs corrosion resistance.

- In case of visible contamination: The occurrence of flash rust, discoloration, or other surface contaminants indicates a compromised passive layer.

- Before use in corrosive environments: In aggressive environments, such as maritime applications or the chemical industry, an optimal passive layer is essential for the longevity of the components.

What are the benefits of passivation?

Passivation of stainless steel offers several crucial benefits:

- Increased corrosion resistance: By removing free iron particles and forming a dense chromium oxide layer, stainless steel becomes more resistant to corrosive environments.

- Improved hygiene: In industries such as food and pharmaceuticals, a clean and corrosion-resistant surface is essential to avoid contamination.

- Extended lifespan: Passivated stainless steel components have a longer lifespan because they are less prone to corrosion and associated damage.

- Aesthetic advantages: An intact passive layer prevents unsightly rust spots and maintains the shiny appearance of stainless steel.

What are the benefits of passivation?

There are various methods for passivating stainless steel, selected based on application and specific requirements:

- Chemical passivation: Here, the workpiece is immersed in an acid bath, typically consisting of nitric or citric acid. This process removes free iron particles and promotes chromium oxide layer formation.

- Electrochemical passivation: This method uses an electrochemical process in which the workpiece serves as an anode in an electrolytic cell. Applying voltage accelerates and controls the formation of the passive layer.

- Pickling and passivating: In some cases, pickling is performed before passivation to remove scale, discoloration, or other oxidations. Passivation then follows to regenerate the protective chromium oxide layer.

- Passivation with TIG-MAX: The TIG-MAX® system combines cleaning, polishing, and passivation in a single step. Using a conductive brush and a specially developed cleaning fluid, iron oxides formed during welding are removed. Simultaneously, the surface is activated through targeted heat development, forming a new chromium oxide layer immediately. This results in a stable, corrosion-resistant passive layer – all without aggressive pickling pastes or separate post-treatment steps. The method is effective, material-friendly, and safe for health.

Our welding seam cleaning devices at a glance