Technical tips after welding seam cleaning

In order to avoid soiled or smudged workpieces or the formation of edges or tempering colors, it is important to correct the welds correctly after cleaning.

Version 1

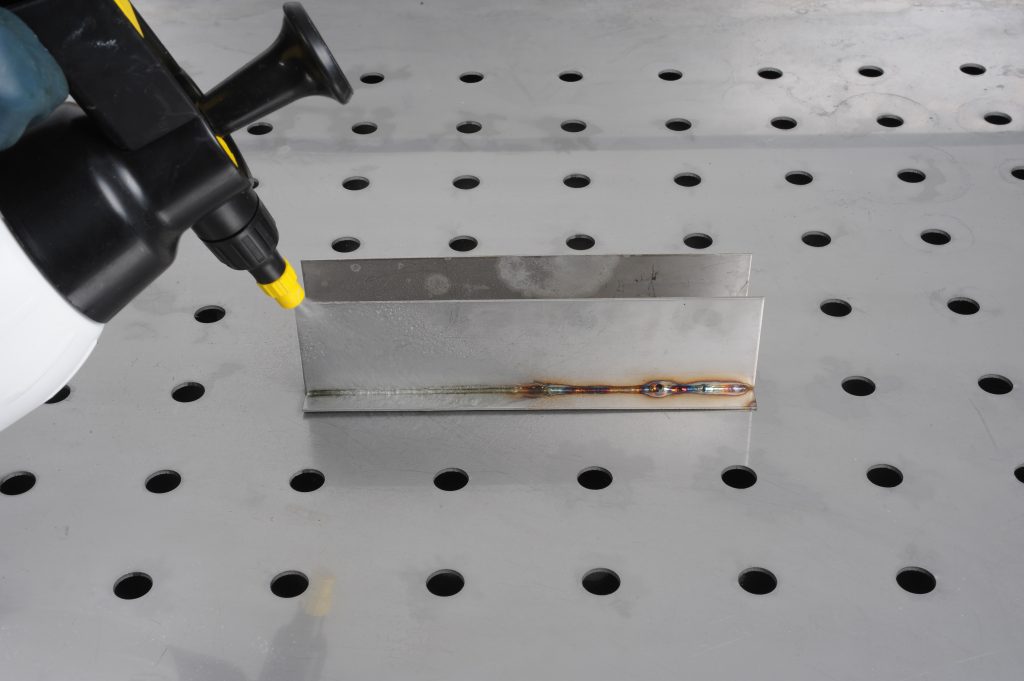

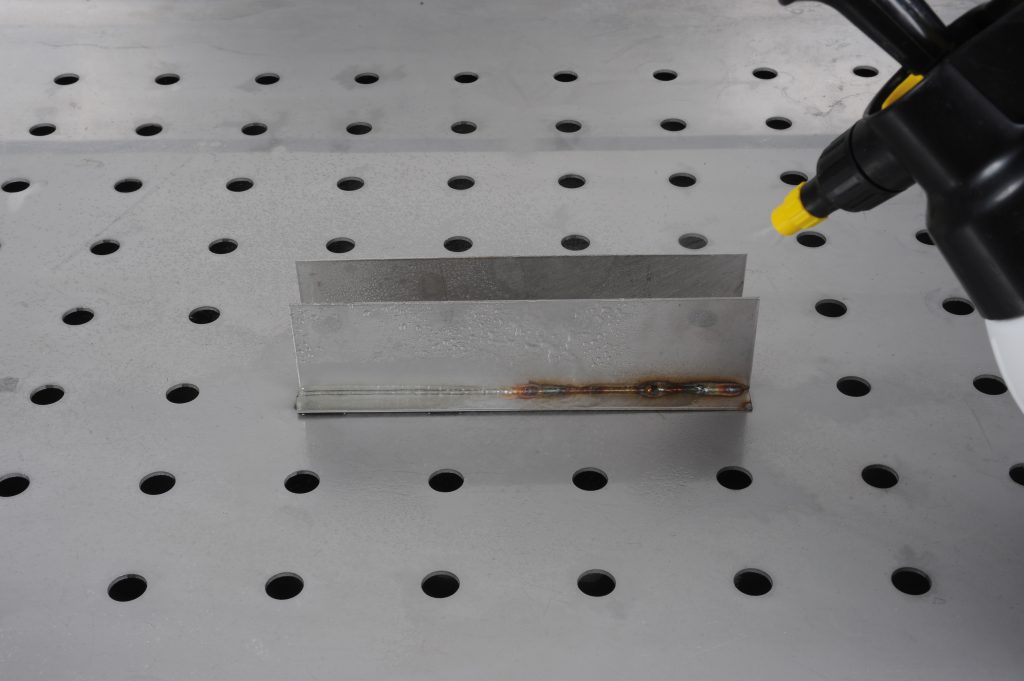

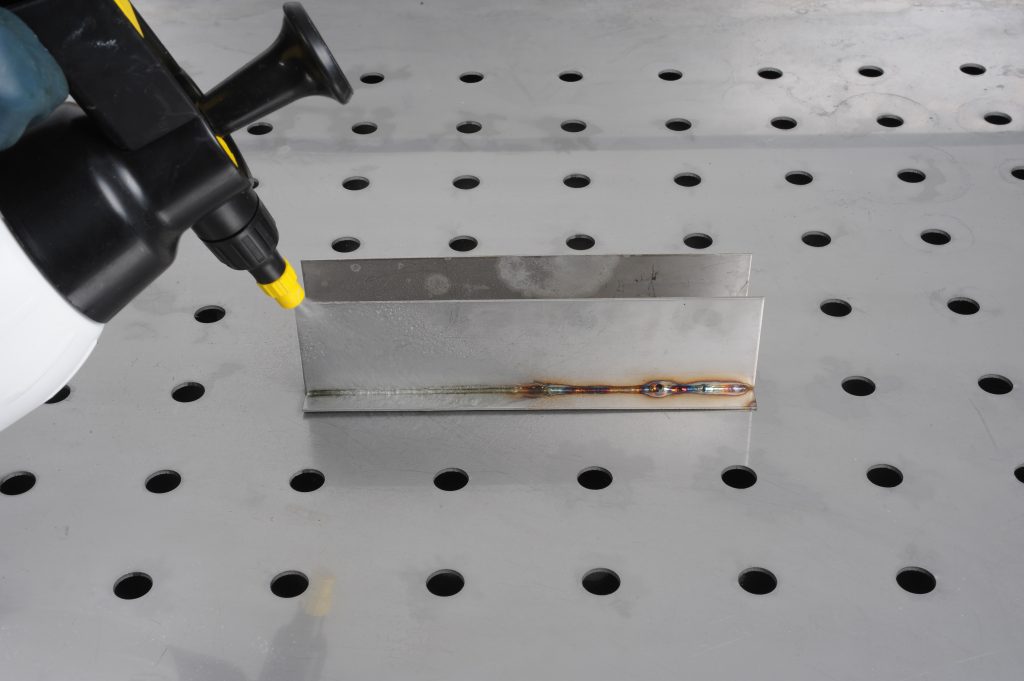

1. Neutralize

Fill the neutralizing fluid (e.g., TC-510) into a pressure pump sprayer or spray bottle. Spray the neutralizer on the treated surface. Be sure to spray the entire surface of the weld cleaning fluid.

2. Rinse off

Rinse the treated area with clean water. Use plenty of water and be sure to remove all liquid from the surface. The rinsing of the treated surface can be done for example with a high-pressure cleaner.

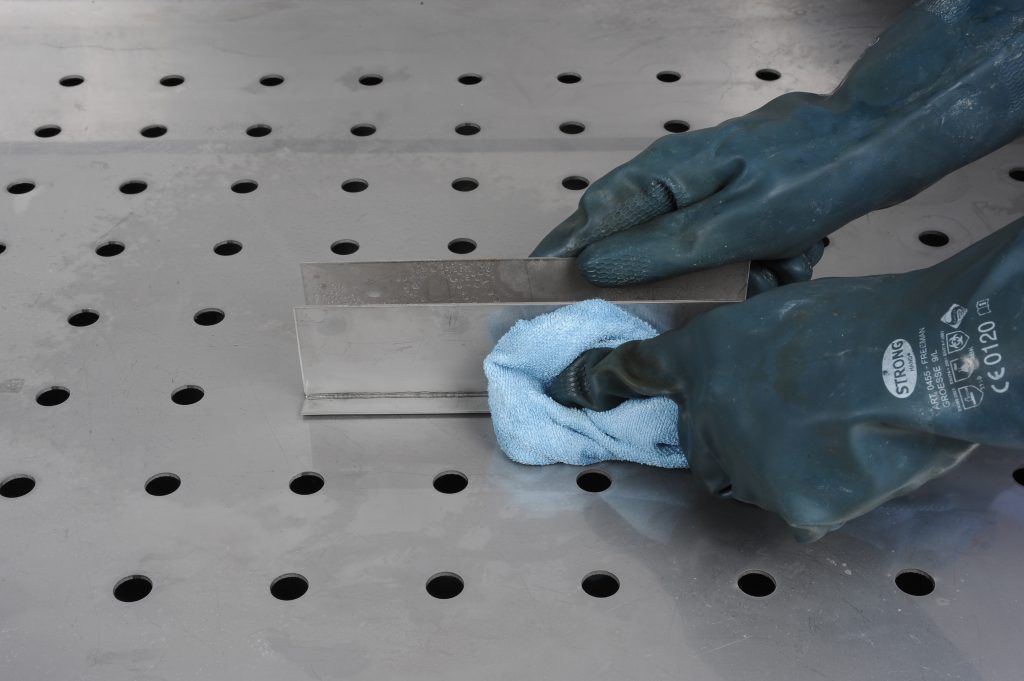

3. Drying

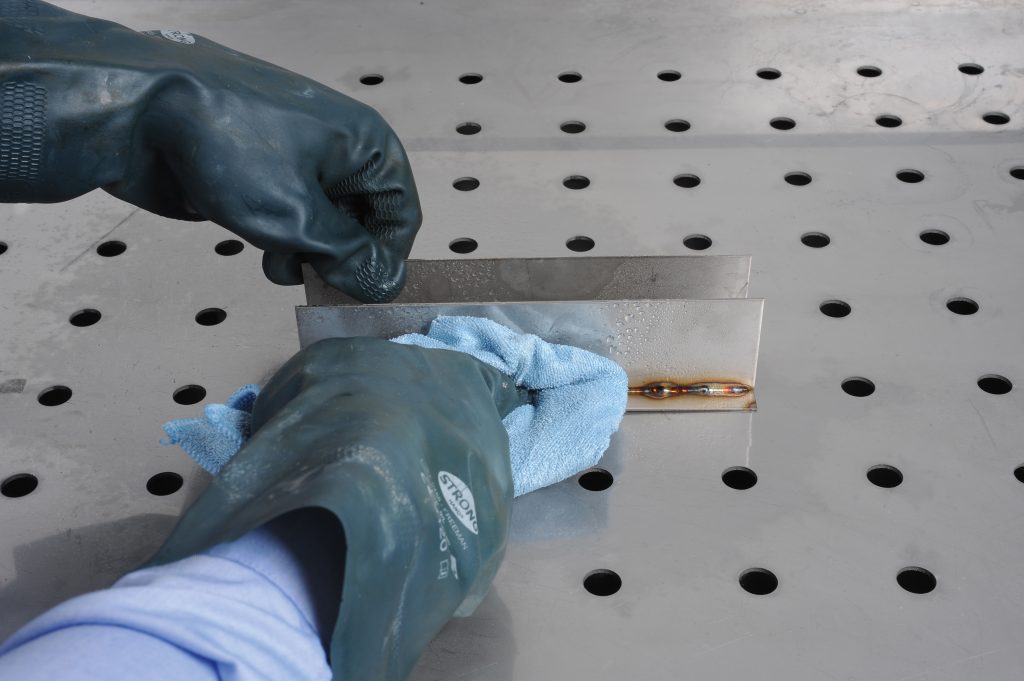

Now dry the treated area with a clean microfibre cloth as needed.

Version 2

1. Neutralize

Fill the neutralizing fluid (e.g., TC-510) into a pressure pump sprayer or spray bottle. Spray the neutralizer on the treated surface. Be sure to spray the entire surface of the weld cleaning fluid.

2. evaporation

Use our special steam cleaner to remove the liquid from the surface. Drive over the treated area as often as necessary until all residues of the cleaning fluid have been removed.

3. Drying

Now dry the treated area with a clean microfibre cloth as needed.